In-Cell CTP Technology: A Deep Technical Overview for Engineers Introduction

In-Cell Capacitive Touch Panel (CTP) technology represents one of the most complex integrations in modern display engineering. Unlike traditional touch modules—G/G (Glass-Glass), OGS (One-Glass-Solution), or On-Cell architectures—In-Cell embeds the X–Y touch electrodes directly within the TFT (Thin-Film Transistor) layer of the LCD or OLED stack.

Instead of adding a discrete touch sensor layer laminated above the display, In-Cell merges display pixel-driving circuits and mutual-capacitive touch detection circuitry within the same substrate. This reduces stack height, improves optical throughput, and changes the entire electrical architecture of touch sensing, particularly in noise-dominated environments.

Technology Architecture

1. Electrode Formation Inside the TFT Layer

In In-Cell designs, the touch electrodes are integrated on the same plane as one of the TFT layers:

LCD In-Cell

- Touch electrodes are formed on the array substrate, typically above the pixel electrodes but below the color filter.

- The electrodes often share routing layers with display lines (Gate/Source), requiring very tight electromagnetic compatibility (EMC) control.

OLED In-Cell

- Touch electrodes are patterned on the encapsulation (TFE) or integrated with the anode structure, depending on the AMOLED stack.

2. Mutual-Capacitive Touch Sensing

Most In-Cell designs use mutual capacitance due to the limited sensing area:

- TX electrodes send a high-frequency excitation signal.

- RX electrodes capture changes in mutual capacitance caused by a finger or conductive object.

- The “node capacitance” per intersection is typically 0.3–1.0 pF, much lower than in on-cell modules (3–10 pF), requiring advanced noise filtering.

3. Integrated Display Noise Management

The biggest engineering challenge: display noise generated by:

- Gate driver switching

- Source driver voltage transitions (15–20 V typically in a-Si LCD)

- Vcom flicker

- PWM backlight switching

- OLED pixel refresh current

Therefore, In-Cell systems use:

- High-order digital filters (FIR/IIR)

- Frequency hopping (10–300 kHz)

- Differential sensing

- Synchronous sampling aligned with blanking intervals

This co-design between touch IC and display driver (DDIC + TDDI) is what makes In-Cell solutions competitive.

TDDI: Touch + Display Driver Integration

Modern In-Cell screens rely heavily on TDDI (Touch and Display Driver Integration) ICs.

Engineering benefits:

- Shared timing control

- Coordinated noise suppression

- Lower power consumption (fewer ICs, fewer lines)

- Reduced BOM cost

- Better performance in wet-touch and glove-touch modes.

Engineering constraints:

- Limited customization for industrial or rugged devices

- Requires panel manufacturer + IC vendor collaboration early in design

- Higher NRE costs for custom sizes

Advantages (Engineering Level)

1. Structural & Optical

- Eliminates at least one glass/plastic layer → reduces reflections by ~4–8%

- Optical transmittance improvement of 3–10% depending on AR coatings

- Better luminance uniformity due to reduced air gaps

2. Form Factor

- Thickness reduction: 0.3–0.7 mm compared to On-Cell

- Weight savings up to 10–15 g on handheld devices

- Narrower bezels possible due to integrated routing

3. Electrical Performance

- Lower touch latency (5–15 ms typical)

- Better signal-to-noise ratio (SNR) in edge-area rejection

- Reduced parasitic capacitance compared to overlay sensor stacks

Disadvantages (Engineering-Level Detail)

1. Limited Ruggedization

Because electrodes are embedded inside the panel:

- Thick cover lenses (up to 6 mm) reduce touch sensitivity

- Wet-touch and gloved-touch performance depends heavily on TDDI tuning

- Industrial operability (EMI immunity >10 V/m) may require shielding films

2. Complex Manufacturing Processes

In-Cell production requires:

- Additional photolithography steps

- More precise TFT patterning tolerances

- Coordinated DDIC + TDDI tuning

- Calibration of touch electrode linearity in mass production

Yield drops significantly for:

- Larger sizes (>10 inches)

- High-resolution OLED In-Cell due to fine-pitch electrodes

- Harsh environments (sunlight-readable, high-brightness modules)

3. Repair Limitations

If a touch function fails:

- The entire display + electrode stack must be replaced

- No option to replace laminated touch glass like in G/G or OGS

Key Application Sectors

1. Consumer Electronics

- Smartphones, tablets, laptops

- High emphasis on form factor and optical clarity

- In-Cell is now the dominant technology in premium smartphones

2. Portable Medical Devices

- Low weight

- High optical performance

- Multi-touch with precise finger detection

3. IoT & Smart Home Products

- Sleek, compact enclosures

- Integration with low-power microcontrollers

4. Automotive Interiors

Used mainly for:

- Center stack displays

- Secondary infotainment screens

- Less common for primary HMIs requiring thick, laminated cover lenses or haptic overlays.

5. Industrial HMIs

Used selectively where:

- Touch precision matters

- Device depth must be minimized

Not ideal for extreme durability or glove-dominant usage.

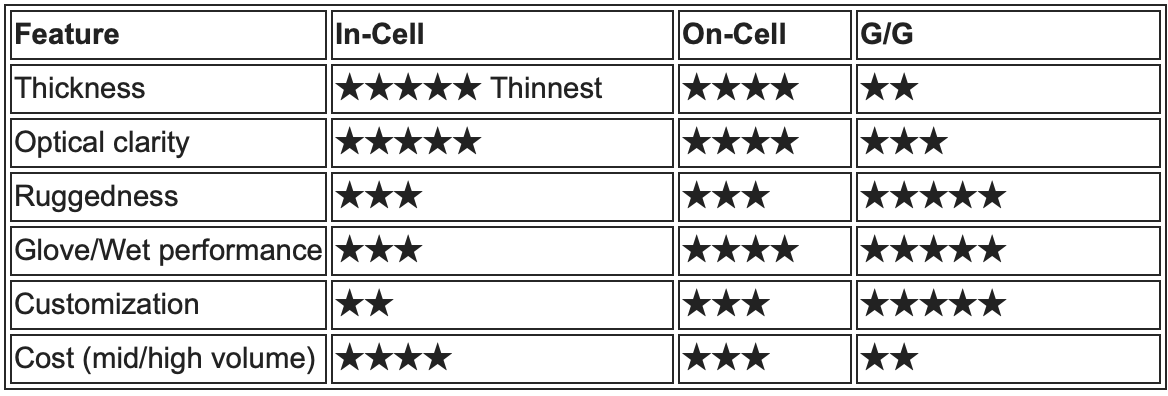

Manufacturing Insight: When to Choose In-Cell vs. On-Cell vs. G/G

If your product requires:

- High brightness

- Thick cover glass

- Custom shapes

- Harsh EMC environments

Then On-Cell or G/G remains the better design choice.

Summary

In-Cell CTP technology offers clear engineering advantages—reduced thickness, improved optical performance, high touch accuracy, and TDDI-driven efficiency. It delivers a premium user experience, especially in handheld or compact devices where optical clarity and responsiveness dominate requirements.

However, engineers must account for:

- Noise suppression challenges

- Reduced ruggedization

- More complex manufacturing

- Lower customization flexibility

For high-volume consumer, medical, and slim industrial products, In-Cell remains one of the most effective touch architectures available today.

If you need support choosing the right display architecture, customizing touch performance, or sourcing In-Cell modules for your next design, contact me at: [email protected]

I’ll be glad to support your engineering and sourcing requirements.

E-mail: [email protected]

Tel: +972.77.540.1143